AlSiC

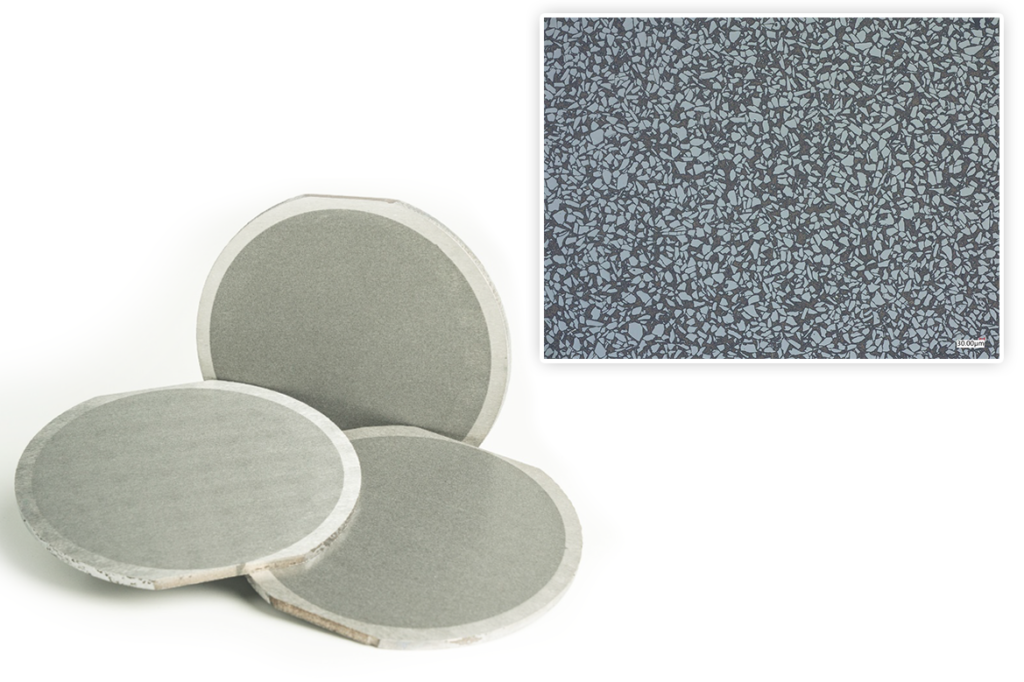

AlSiC composite material

Ideal material for thermal management

Aluminum Silicon Carbide (AlSiC) is an advanced ceramic matrix composite (CMC) that perfectly combines the lightweight and excellent machinability of aluminum with the superior rigidity, low coefficient of thermal expansion, and high thermal conductivity of silicon carbide. This unique combination of materials makes it perform excellently in many demanding application environments, making it an ideal choice for various industries seeking breakthrough solutions.

> Features

- Adjustable coefficient of thermal expansion

By adjusting the volume fraction of silicon carbide particles, the coefficient of thermal expansion (CTE) of the material can be precisely controlled to perfectly match semiconductor chips (such as Si, GaN, SiC) or ceramic substrates (such as Al2O3, AlN). - Excellent heat dissipation performance

The thermal conductivity of AlSiC (>200 W/m·K) is comparable to that of pure aluminum and higher than that of most traditional ceramic materials. - Lightweight

The density of AlSiC is approximately 2.9 ~3.1g/cm³, which is only 1/3 of that of copper (Cu) and 1/5 of that of copper tungsten (CuW) or copper molybdenum (CuMo) alloys. - High Specific Stiffness and Strength

Due to the addition of silicon carbide particles, the Young’s Modulus of AlSiC is much higher than that of aluminum alloys. - Isotropic Properties

Unlike fiber-reinforced composite materials, the physical properties (thermal conductivity, expansion, strength) of particle-reinforced AlSiC are consistent in all directions, which simplifies engineering design.

> Specification Parameters

| Property | UICA07 | UICA08 | UICA09 |

| Density | ≒3.0 g/cm³ | ≒2.98 g/cm³ | ≒2.95 g/cm³ |

| Thermal Conductivity | ≥ 200 W/m·K | ≥ 200 W/m·K | ≥ 200 W/m·K |

| Coefficient of Thermal Expansion, CTE | 7~8 ppm/°C | 8~9 ppm/°C | 9~10 ppm/°C |

| Tensile Strength | ≥ 230 MPa | ≥ 220 MPa | ≥ 200 MPa |

| Compressive Strength | ≥ 500 MPa | ≥ 500 MPa | ≥ 500 MPa |

| Hardness | ≥ 80 HRB | ≥ 80 HRB | ≥ 80 HRB |

| Electrical Resistivity | ≤ 3.0×10^-4 μΩ·cm | ≤ 3.0×10^-4 μΩ·cm | ≤ 3.0×10^-4 μΩ·cm |

| Applications | Electronic Packaging Materials / Thermal Substrates / High-Performance Structural Components | Electronic Packaging Materials / Thermal Substrates / High-Performance Structural Components | Electronic Packaging Materials / Thermal Substrates / High-Performance Structural Components |

Contact us for more information